As an upgraded version of the 2BE3 series vacuum pumps, the new 2BE4 product has improved the bearings. By optimizing the discs and impellers, it has enhanced the internal fluid efficiency, achieving energy savings of 6 to 8%. A connection method for flushing the pump can also be selected to enhance the pump's cleaning capacity and extend its service life.

The design fully takes into account the requirements of some harsh working conditions to ensure the durability and reliability of the pump during low-cost operation. It is widely used in industries such as papermaking, power, mining, and chemical processes. Each model of pump is equipped with a pump casing lined with polyisoprene rubber. To meet the requirements of more demanding working conditions, different materials such as stainless steel, stainless steel composite coating or epoxy material coating can be selected for manufacturing.

The unique and flexible optimized design of the intake and exhaust ports allows for both top and side exhaust methods, facilitating on-site installation. Within the limited installation space, the 2BE4 can be equipped with an overhead separator, reducing the occupied space and eliminating the need for a trench.

Throughout the entire vacuum range, the 2BE4 pump can maintain its allowable high-efficiency operation without altering its structure. It adopts an intermediate partition design, with an intake pressure difference of 330mbar, achieving dual functionality in one machine. There are large inspection ports on both sides of the pump body, which is more conducive to the inspection and maintenance inside the pump.

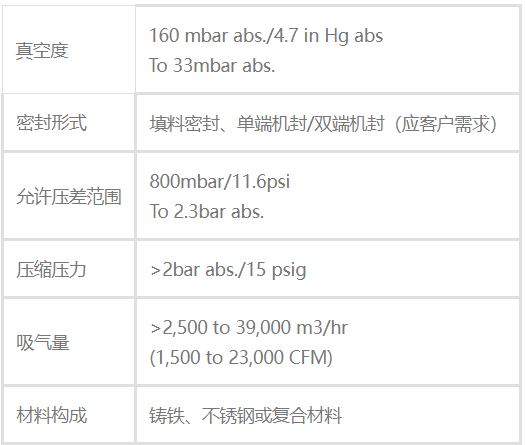

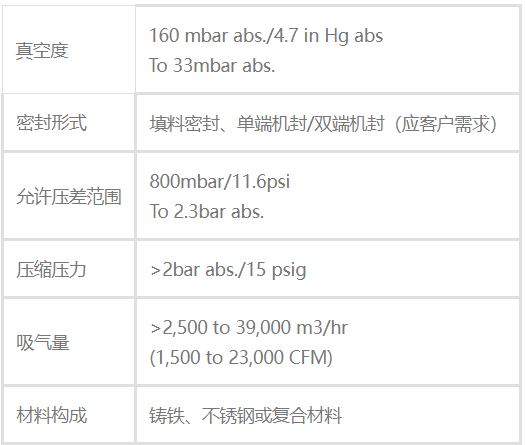

When used as a vacuum pump, the 2BE4 series has an intake volume ranging from 2500 m ³ /hr to 33,000 m ³ /h, and a vacuum degree up to 160 mbar abs. When used as a compressor, the gas volume ranges from 3000 m ³ /h to 9500 m ³ /h, and the compression pressure reaches 2.5 bar abs.

2BE4 Basic Date:

Flexible installation

Each model of pump is equipped with a polyisoprene rubber inner lining of the pump casing, which further enhances the pump's corrosion resistance and erosion resistance, and also reduces energy consumption. To meet the demanding applications of more industries, the 2BE4 pump can be manufactured from different materials such as stainless steel, stainless steel composite coating or epoxy material coating.

When the intermediate partition is adopted, each 2BE4 series vacuum pump can operate at two different vacuum degrees. As long as the suction pressure difference between these two parts is less than 330mbar, a 2BE4 can be used as a relatively independent vacuum pump. The significance of this advantage lies in the fact that a smaller number of vacuum pumps can be used, thereby saving space and installation costs.

Regardless of the model and gas volume, the 2BE4 series vacuum pumps can operate very smoothly and quietly. At a distance of 1 meter from the pumps, the noise levels of all the pumps are between 72 and 85 decibels.

鲁公网安备 37030402001448号

鲁公网安备 37030402001448号