E-Mail:ttpump@163.com

Phone:+86-13615332800

Tel:+86-0533-4160533

Address:3 Yanhe East Road, Boshan, Zibo, Shandong

Single stage or two stages, double-suction or single-suction, radially split casing, between-bearings, heavy duty process pumps,centerline mounted. The pump complies with APl 610 standard BB2 type.

SM R pumps are designed upon hard or heavy duty pumping conditions, for pumping clean or slightly contaminatd water, oil,liquefied gas, hydrocarbon, etc.

■ Refineries , petrochemical plants

■ Gas processing

■ Coal processing

■ Power plants, heat servicing system

■ Offshore installation

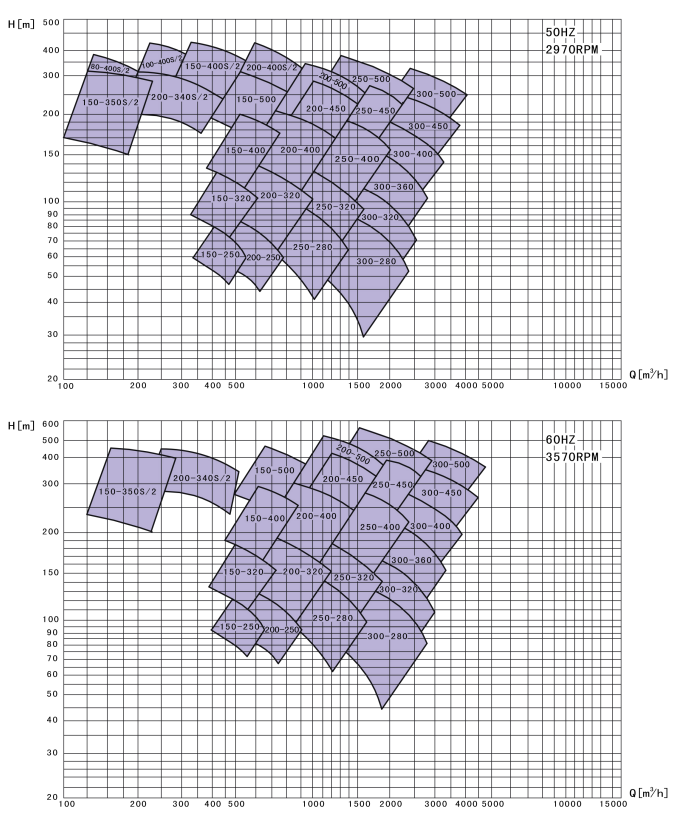

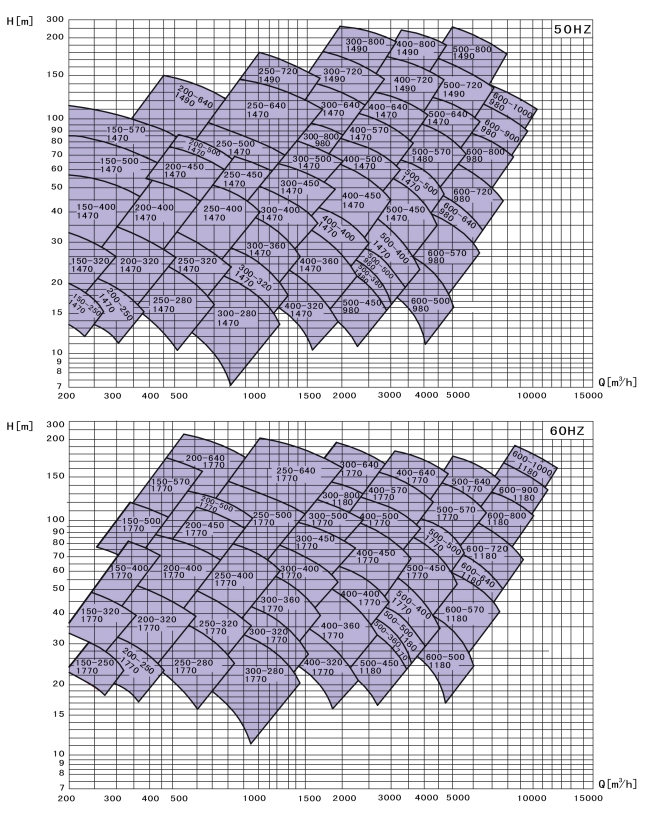

Capacities Q: ~10000m³/h

Heads H: ~450m

Operating pressure P:~5.0MPa

Operating temperature t: -45℃~+450℃

① Series

② Discharge branch diameter (mm)

③ Nominal impeller diameter (mm)

④ Impeller type symbol (as below)

⑤ Pump stages (has no if single stage)

⑥ R means radially split casing

| Structural description | SymbolS |

| Single-stage, double-suction impeller structure | SM400-450R |

| Double-stage, double-suctionimpeller structure | SM400-450/2R |

| Double-stage, single-suction impeller structure | SM400-450S/2R |

| First stage double-suctiorn impeller and second | SM400-450SS/2R |

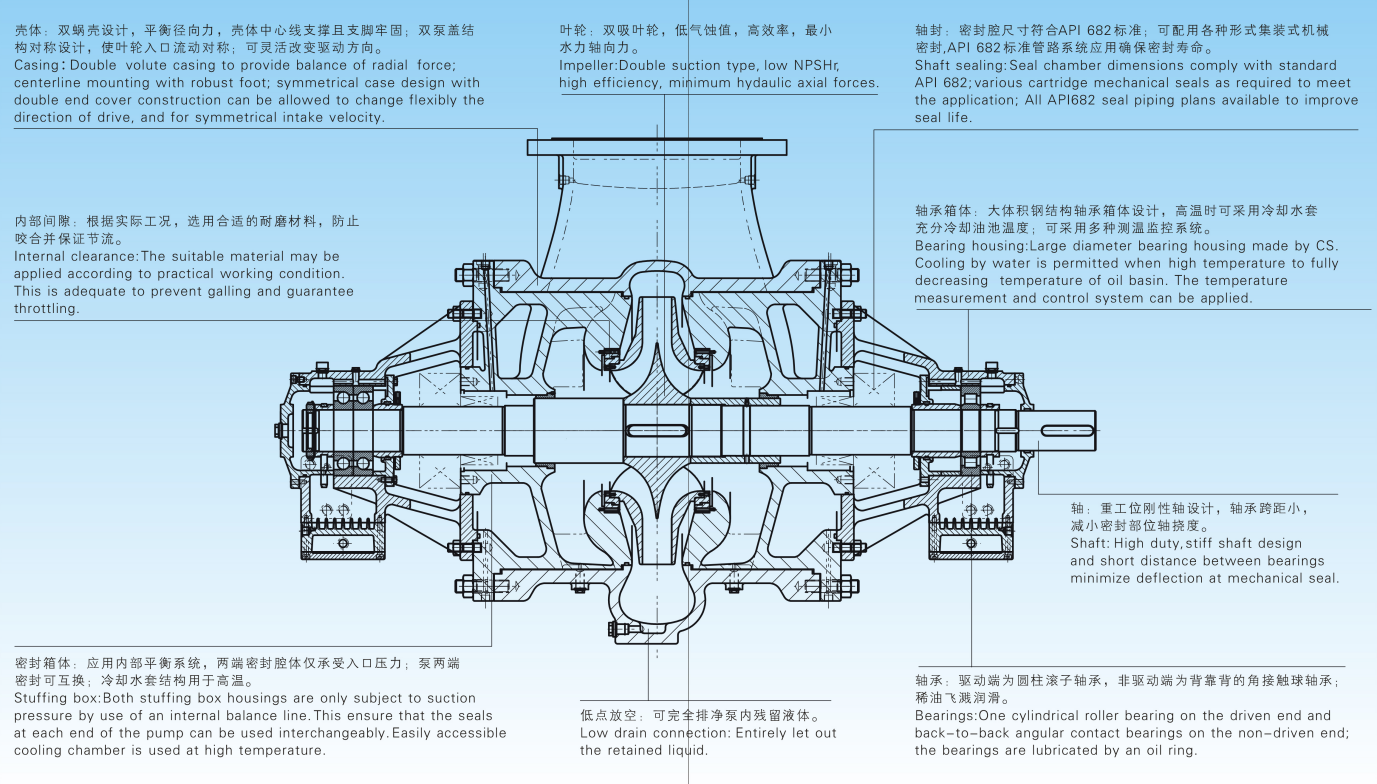

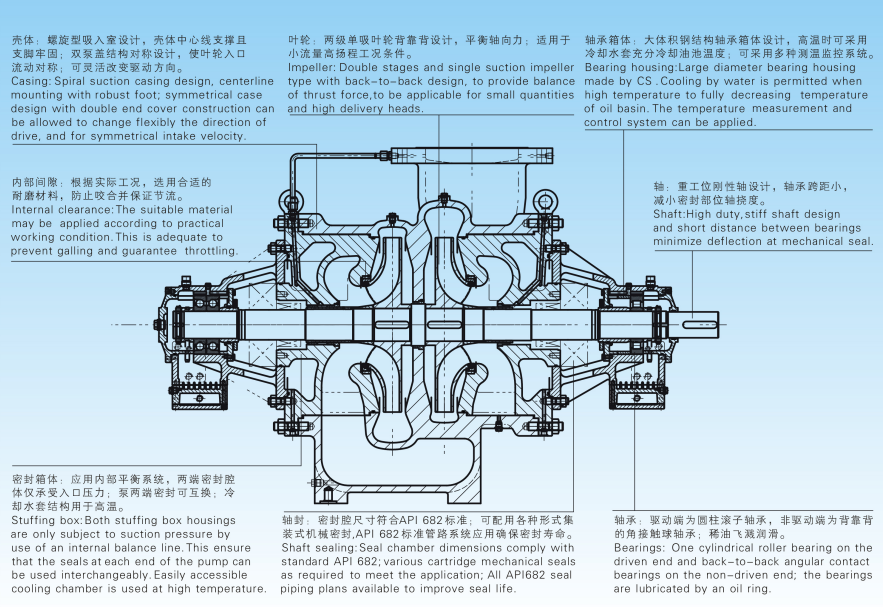

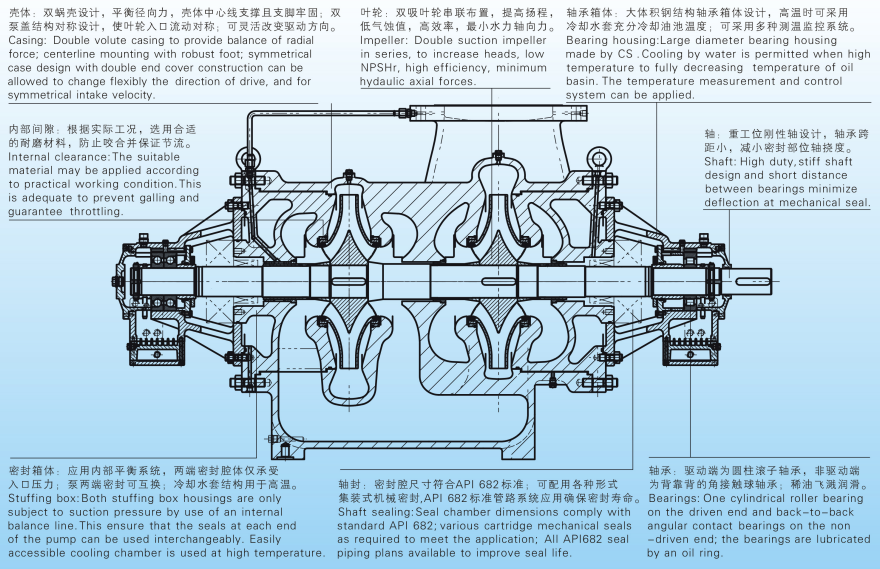

◆Hydraulic design: Double or single suction.single or double stage, volute discharge casing,and spiral suction casing.

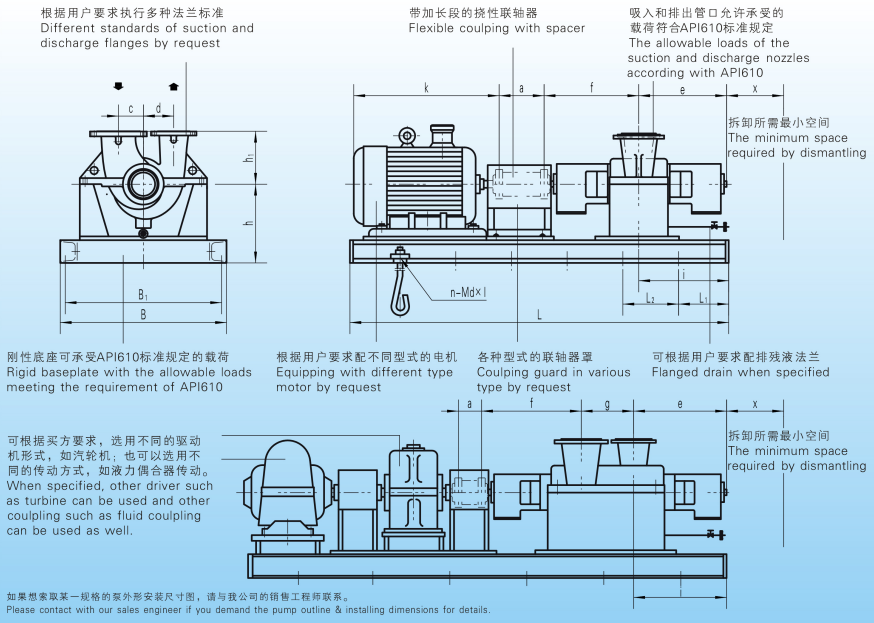

◆Casing: Top discharge, top suction, nozzles loadcompliance with APl 610, radially split,centerline support. Casing cover distributed symmetrically.

◆Flange: The suction and discharge nozzles with same pressure grade, are vertically arranged.Allowable nozzle loadings complie with APl610.

◆Shaft seal: Various cartridge mechanical seals available, single, double or tandem mechanical seal with various APl682 auxiliary system.Camber dimension compliance with APl682.The shaft seal box could be cooled by water.

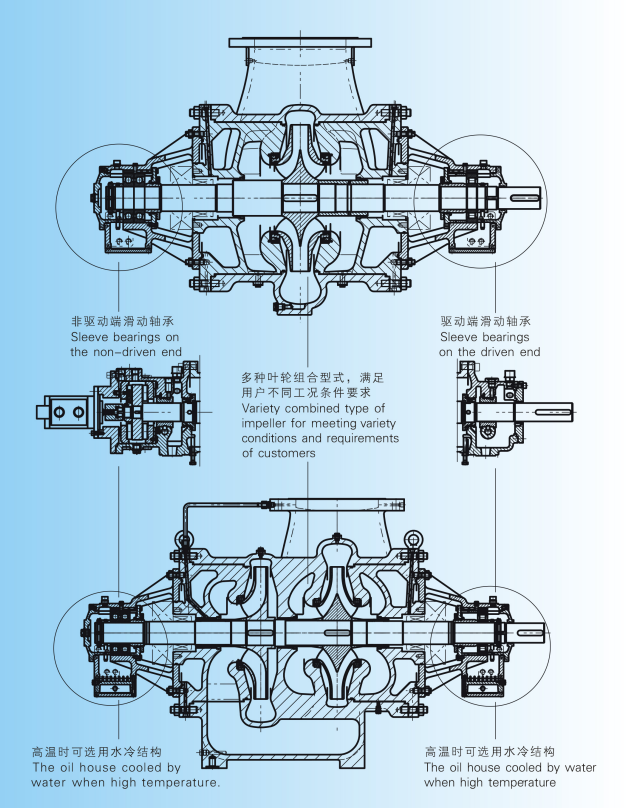

◆Bearing Housing: Large diameter bearing housing with cooling plans made by CS, oil lubrication be available.

◆Shafting: Heavy duty shaft design and bearings support have heavy duty carrying capability.Sleeve bearing or antifriction bearing could be selected.

◆The direction of rotation is clockwise seen from drive end.

Standard APl 610 material classes:S-4.S-5.S-6,C-6,A-8,D-1,D-2.Other choices can be selected when agreed upon by both sides.

Copyright © 2024 ZIBO BOSHAN TIAN TI CACUUM CO.,LTD 备案号:鲁ICP备2020049334号

鲁公网安备 37030402001448号

鲁公网安备 37030402001448号