E-Mail:ttpump@163.com

Phone:+86-13615332800

Tel:+86-0533-4160533

Address:3 Yanhe East Road, Boshan, Zibo, Shandong

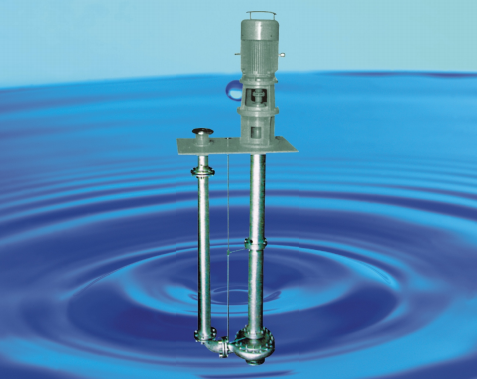

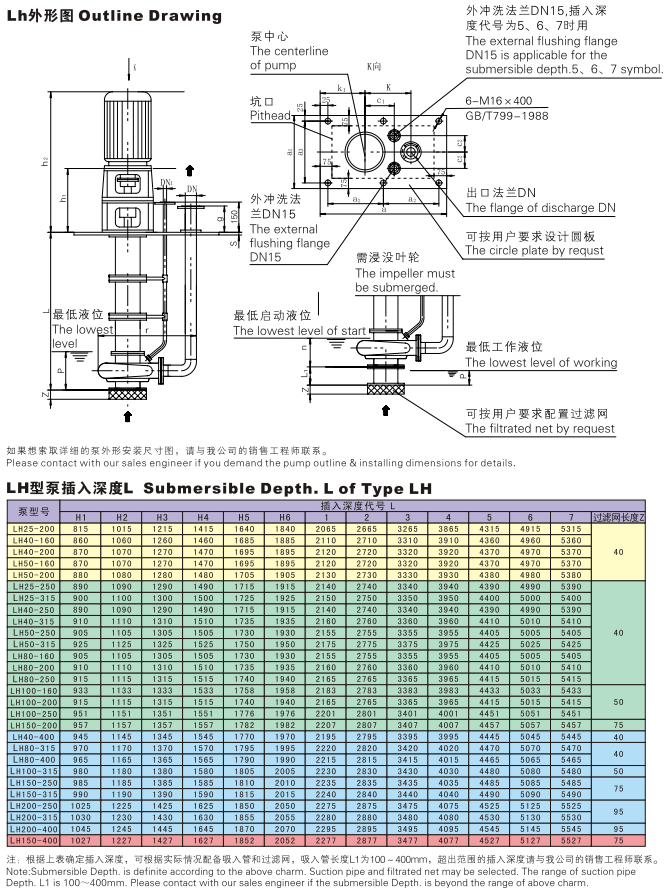

The LH series is vertical single stage,single suction suspend pump with separate discharge.The pumpis designed according with API 610 standards,fornormal VS4 pump type.

LH series pump is designed for most liquid transportation such as various cleaning or contain the solid particle liquid,the normal temperature or high temperature liquid neuter or corrosive liquid etc.The pump canbe used on opening sumppool orclosed pressure container.

■In refineries

■Petrochemical industry

■Sewage treatment factory

■Steel plant

■Electric power plant

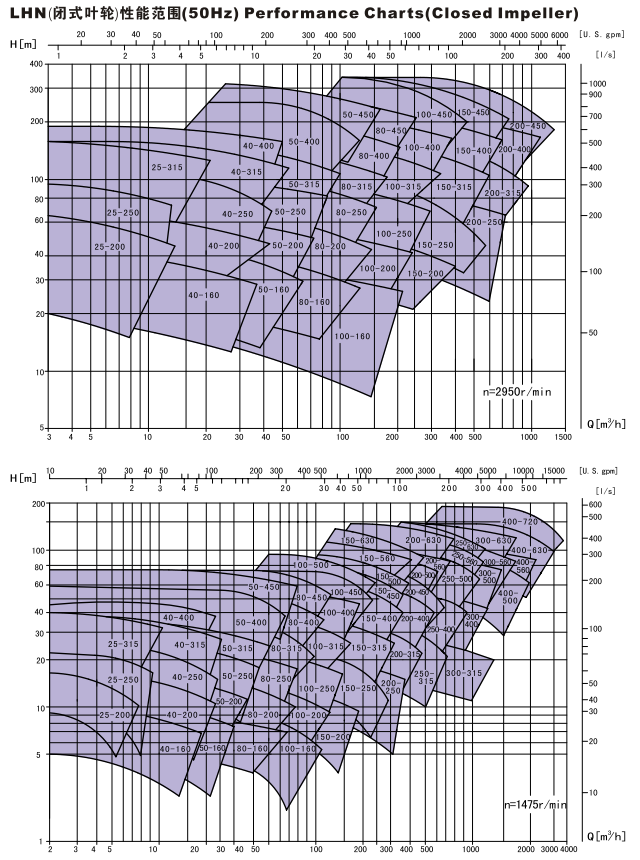

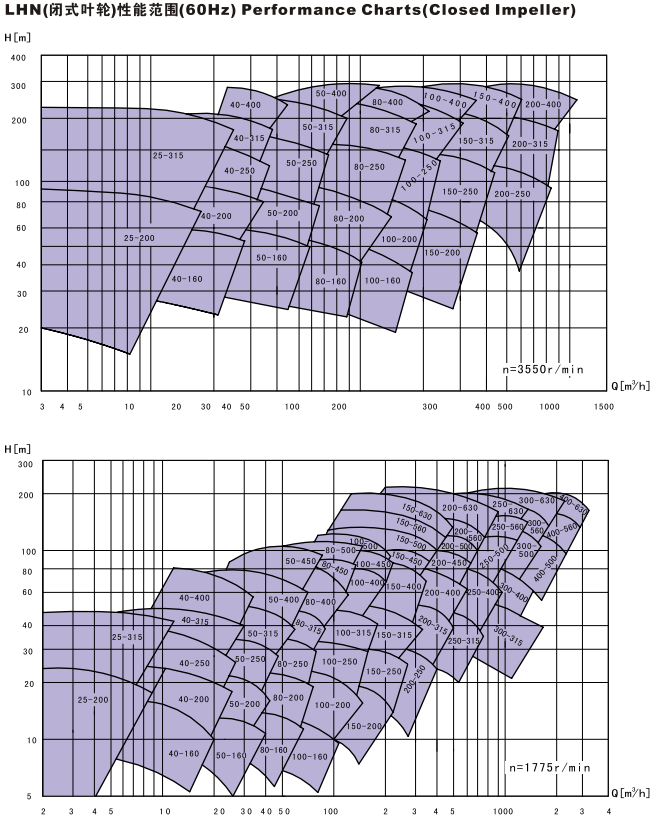

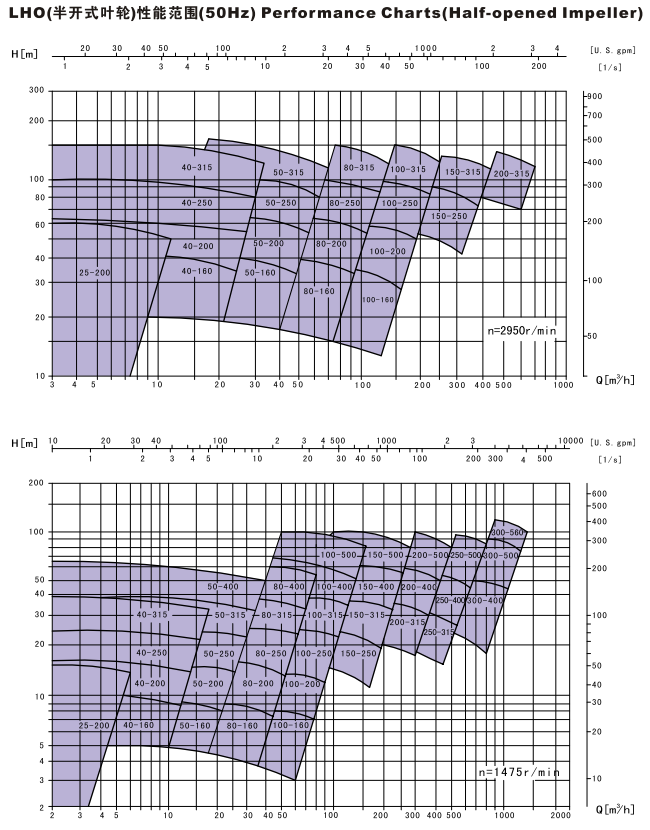

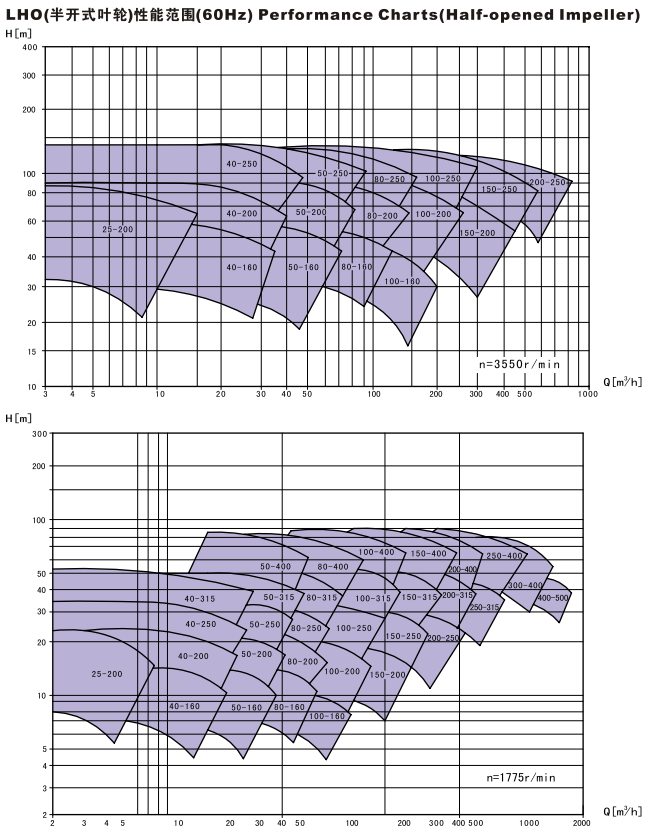

Discharge Branch: 25-400mm

Capacity: ~2600m³/h

Head: ~260m

Pressure: -1.6MPa(2.5MPa when the higher head)

Temp: -20℃-+450°℃

Symbol of centrifugal submersible pump

LH O 40 - 200 GM

① ② ③ - ④ ⑤

①Series name

②Impeller type

N(or non)-Closed impeller O-Half-open impeller

F-discimpeller

E-Openimpeller

③Discharge branch diameter(mm)

④Nominal impeller diameter(mm)

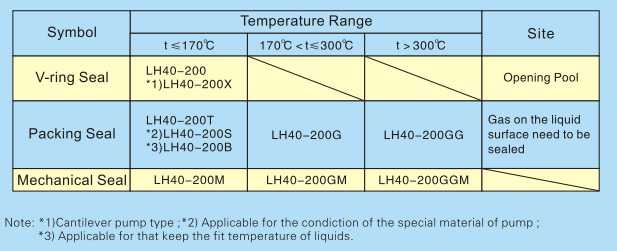

⑤Derivedtype:according to temperature and seal type,as below

Symbolof non-block submersible pump

100 LH W 70 - 22 GM

③ ① ②*⑥ - ⑦ ⑤

⑥Rated capacity(m³/h)

⑦Rated head(m)

②*W-non-block impeller

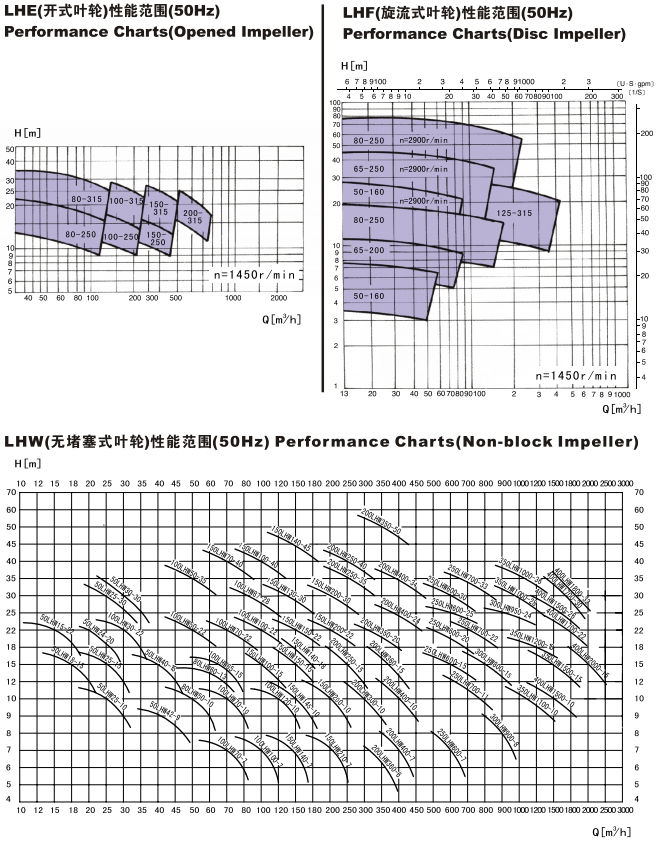

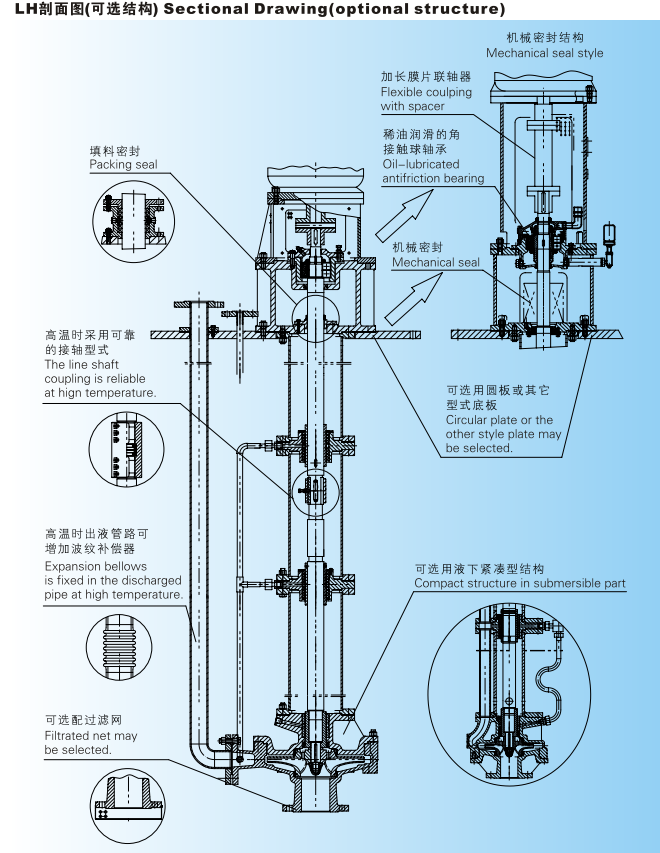

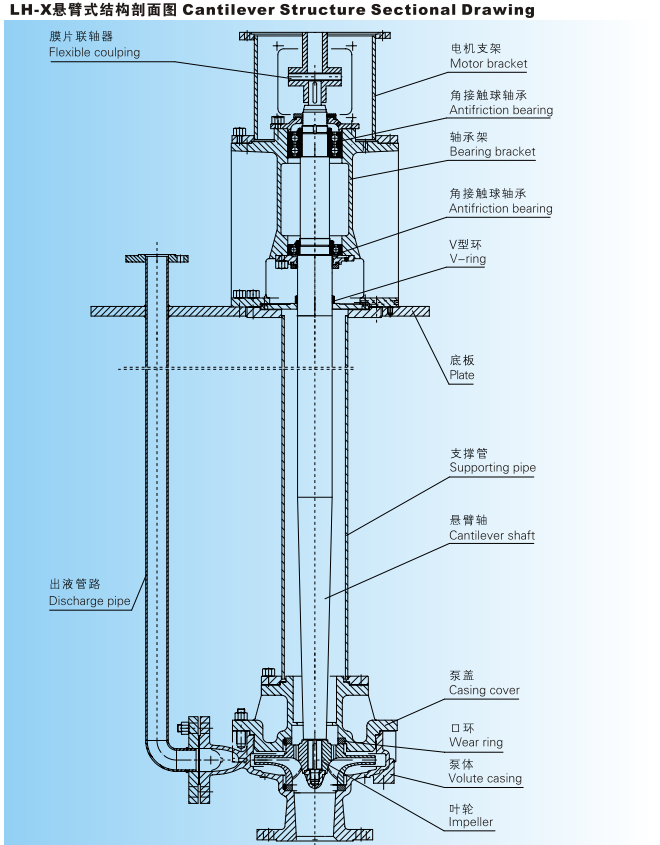

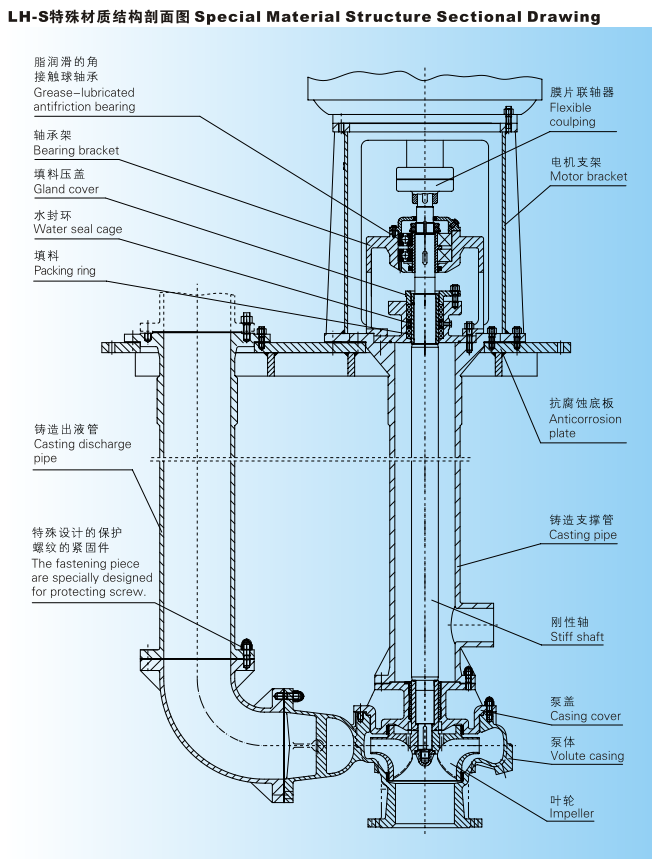

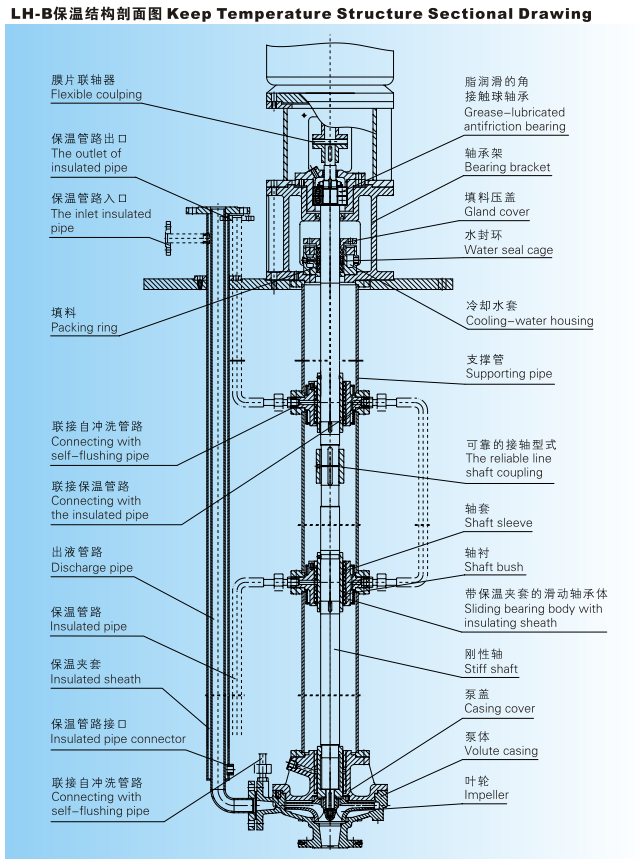

Hydraulic Design:Various hydraulic design can be suitable for great majority conditions.

Line shaft coupling:Safety and reliable line shaft coupling ensure the pump running stability.

Casing:Double volute casting (above 80mm branch size),to be able to balance aradial force to decrease the shaft deflection and plain bearing wearing,and to increase the pump life.

Support structure:Multiple spot supporting,the max spacing between shaft bushings will be able to accord with the APl610 standard Figure 32;Rolling bearing adopt grease lubrication or oil lubrication;Bushings can be lubricated by liquid pumped or liquid outside according to themedium.

Shaft seal:According to condition,v-ring.packing.mechanical seal can be selected.The dimension of seal chamber is according with API 682,and single seal,double seal and tandem seal all can be selected.

Structure:Various structures to be suitable for different severe operation condition.

Rotation:The direction of rotation is clockwise seen from drive end.

API 610 Material grade:S-5,S-6,C-6,A-7,A-8,D-1,D-2,etc.

Alternative material will also be selected according to liquid.

Copyright © 2024 ZIBO BOSHAN TIAN TI CACUUM CO.,LTD 备案号:鲁ICP备2020049334号

鲁公网安备 37030402001448号

鲁公网安备 37030402001448号