E-Mail:ttpump@163.com

Phone:+86-13615332800

Tel:+86-0533-4160533

Address:3 Yanhe East Road, Boshan, Zibo, Shandong

Horizontal, multi-stages, single, ring sectiorcasing, radialy split pumps with high efficiency and low NPSH performance. According to API610 BB4 pump type.

DS series pumps are used for delivering clean,corrosive or non-corrosive liquid and suitable for high pressure services, not suitable for abrasive service.

■ Boiler feed duties up to 210℃

■ Oil field water injection

■ Petrochemical plants

■ Refineries and oil delivery

■ Power plants

■ Pipelines

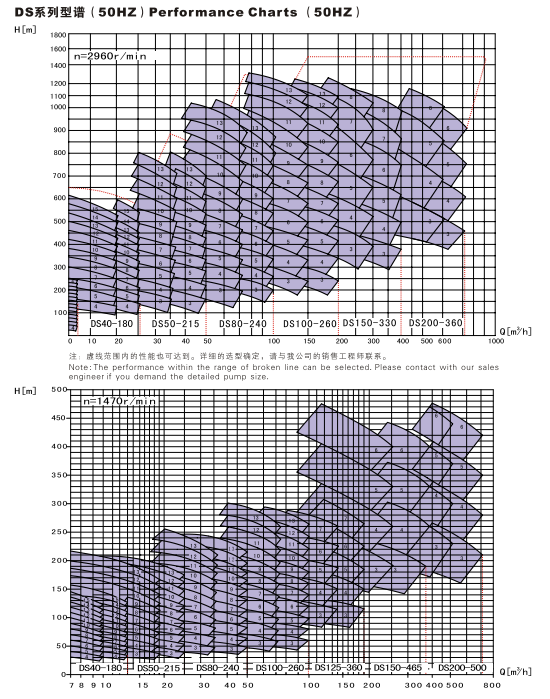

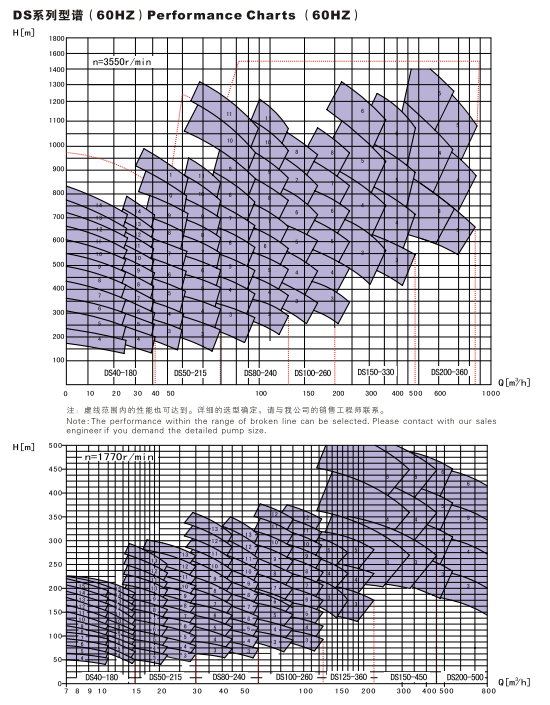

Nozzle sizes DN: 25~200mm

Capacities Q: ~700m³/h

Heads H: ~1400m

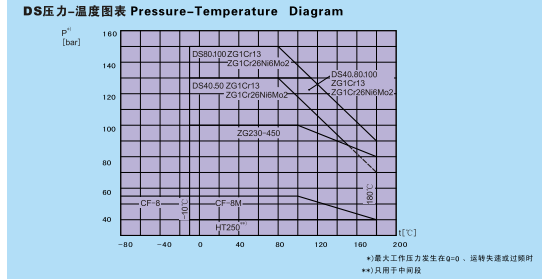

Operating pressure P: ~15.0MPa

Operating temperature T: -50℃~+210℃

DS 50 -215/8 A

① ② ③ ④ ⑤

①Series name

②Discharge branch diameter (mm)

③Nominal impeller diameter (mm)

④Pump stages

⑤Hydraulic model

◆Hydraulic models: Each pump size have two ormore types of hydraulic models, for different operating conditions the best efficient hydraulic model can be selected, high efficiency over a wide range.

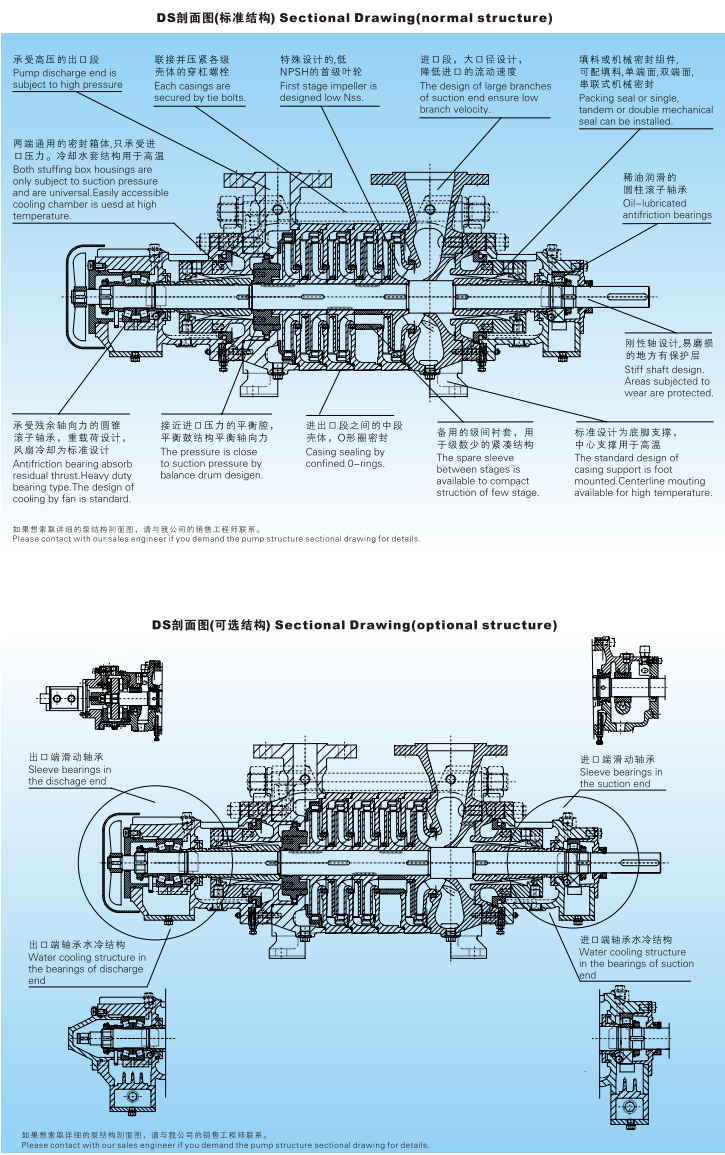

◆Intermediate casing: The intermediate casing are sealed against each other by O rings or by metal compound gaskets and are secured together by tie bolts.

◆Balancing parts: The axial thrust force produced by impellers are mostly balanced by balancing drum and the residual thrust force is absorbed by antifriction bearing

◆Support structures : Normally the pumps are designed with feet below. In case of hot liquid(t>150℃),size 80 and above are supported in pump centerline.

◆Bearings: The antifriction bearing lubricated by oil is reliable and durable. Sleeve bearing could be selected. The bearing house could be cooled by fan or by water.

◆Shaft sealing: The shaft sealing could be soft packing or be mechanical seals depending onthe pumping liquid. The shaft seal box could be cooled by water.

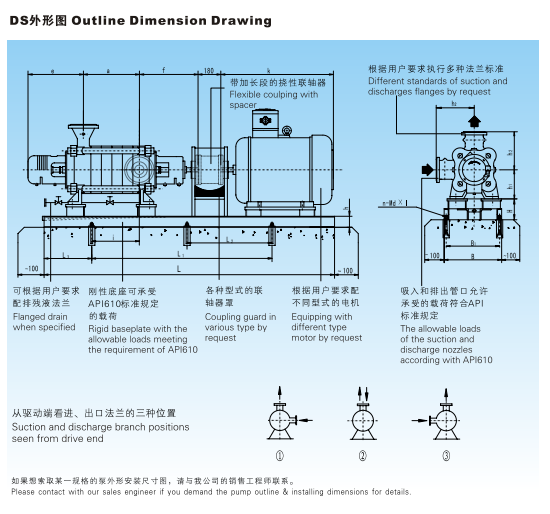

◆Nozzles: The suction and discharge flanges have different pressure ratings. Normally the discharge branch is positioned upward and the suction branch could be selected in any position ( left, right or upward) by request.For pumps with feet positioned in the centerline, the suction branch and discharge branch are upward.

◆Rotaion: The pumps are driven on the suction End. The direction of rotation is clockwise seen from drive end.

Carbon steel,chrome steel,or Cr-Ni-Mo stainless steel.

Standard material classes:S-5,S-6, C-6.A-7,A-8,D-1.Other choices can be selected when needed.Higher operating pressures are possible depending on temperature and materials.

Copyright © 2024 ZIBO BOSHAN TIAN TI CACUUM CO.,LTD 备案号:鲁ICP备2020049334号

鲁公网安备 37030402001448号

鲁公网安备 37030402001448号