E-Mail:ttpump@163.com

Phone:+86-13615332800

Tel:+86-0533-4160533

Address:3 Yanhe East Road, Boshan, Zibo, Shandong

VB series pumps are single suction, mult-stages, radiallysplit, diffuser, vertical can pumps, primarily designed forplants handling liquids with low suction heads. The low NPSH values normally preclude the use of horizontal pumps. Therefore the type vertical can pumps should be used. The pumps are according to APl610 , type VS6.

VB pumps are designed for pumping clean or slightly polluted, cold or hot, chemically neutral or corrosive liquid.

■in refineries

■in chemical and petrochemical plants

■in energy plants

■in cryogenic engineering

■in pipelines

■in offshore industryi

■in transport to liquefied gas

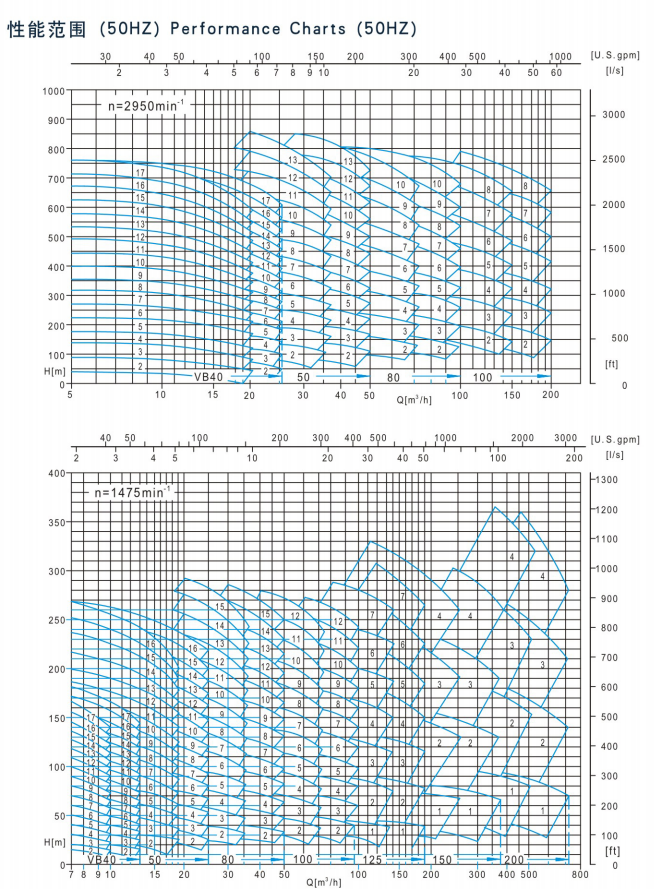

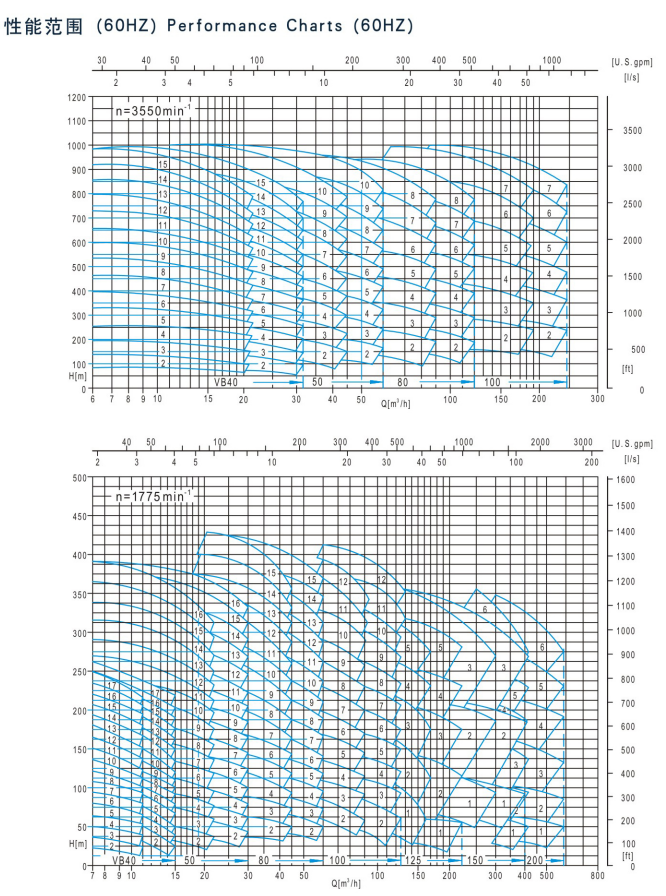

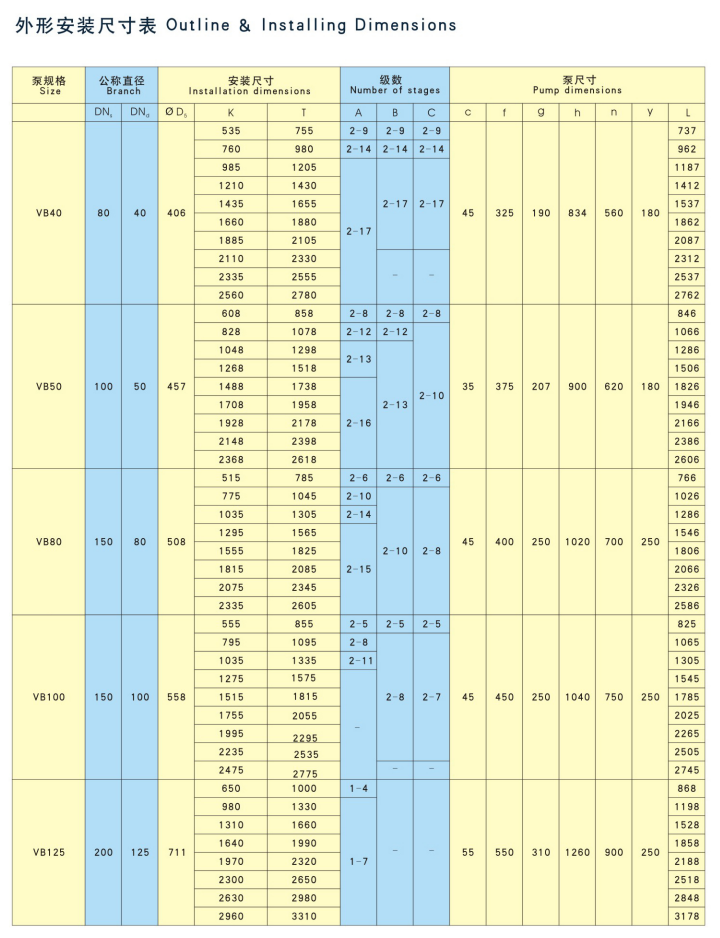

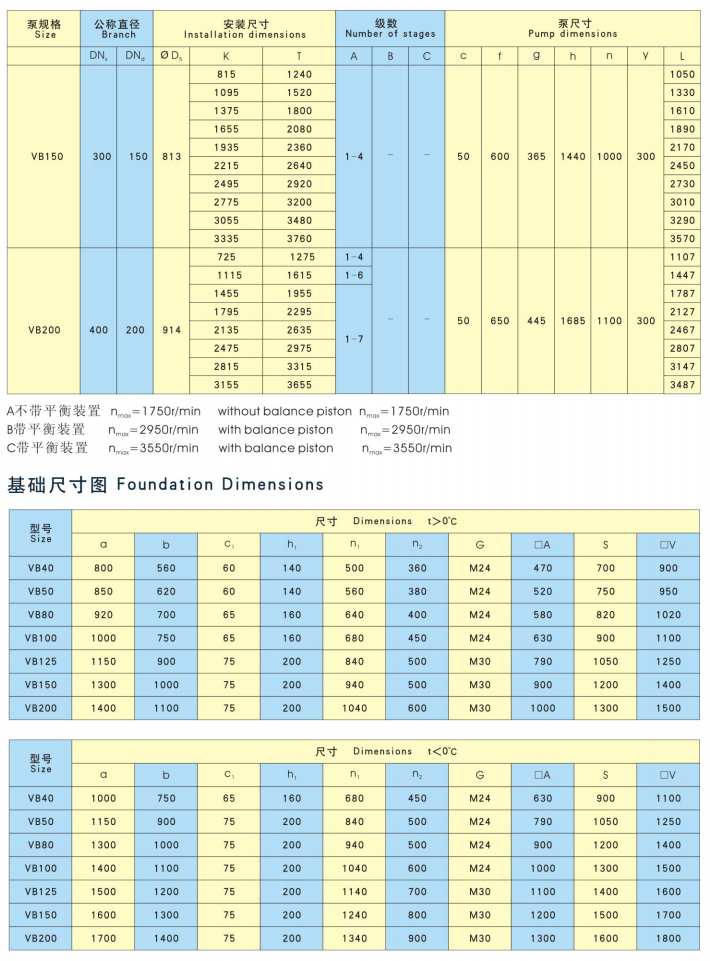

Sizes( DN ) 40 up to 200mm

Capacities( Q ) up to 800m³/h

Heads( H ) up to 800m

Pressure( P ) up to 10.0Mpa

Temperatures( T ) -180℃up to +180℃

①Series

②Discharge branch(mm)

③Stages of impeller

④Hydraulic model, model A or model B

⑤length of can(mm)

⑥ Structure No.

Standard type with can if no any symbolOptions type without can if 01

Carbon steel or stainless steel according to special conditions.

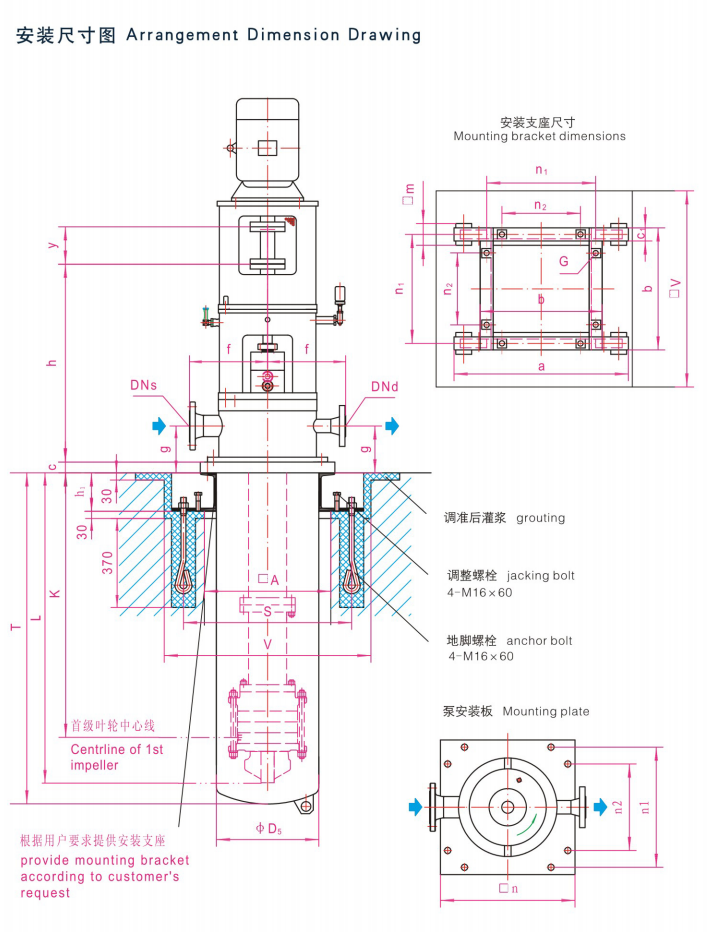

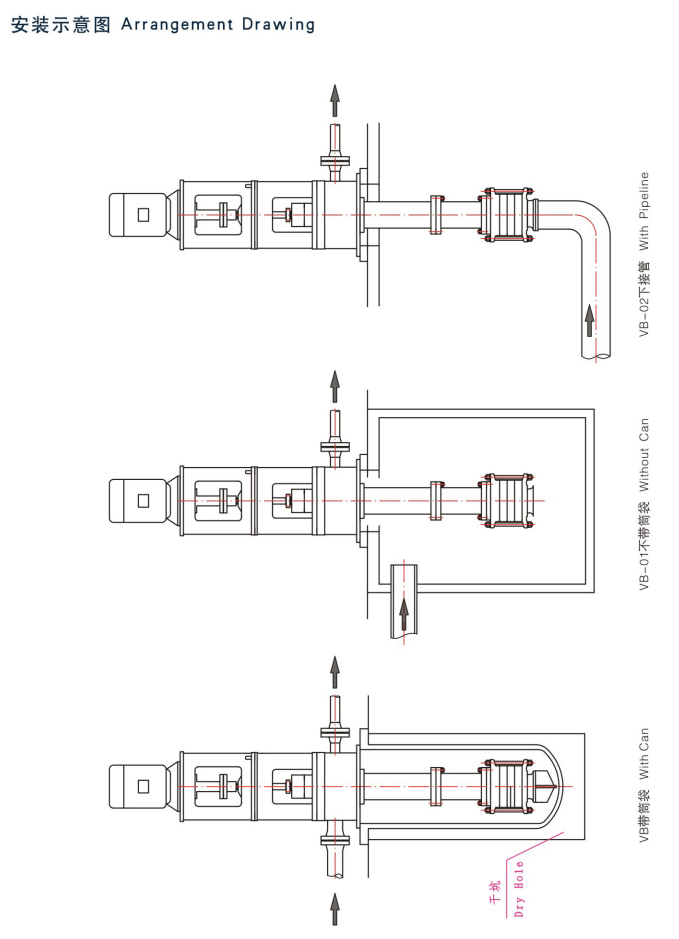

■The pump with can should be arranged in the dryhole. The length of the pump or the can is accordingto the requirement of NPSH. Installed bracket used towill be provided if required.

■The type VB-01 without can should be arranged onthe tank or connected with the pipeline. lt can beused with mult-stage immersion pump. The connection between pump and tank is flange,according to GB or ANSl or consumer request.

■Suction and discharge branches are arranged at 180°(inline) above the mounting flange. Other branch positions are possible.

■Flange pressure: suction branch is 4.0Mpa,discharge branch is 10.0Mpa (In addition to VB150,200).Customer request is optional.

■Direction of rotation anti-clockwise seen from the driven end.

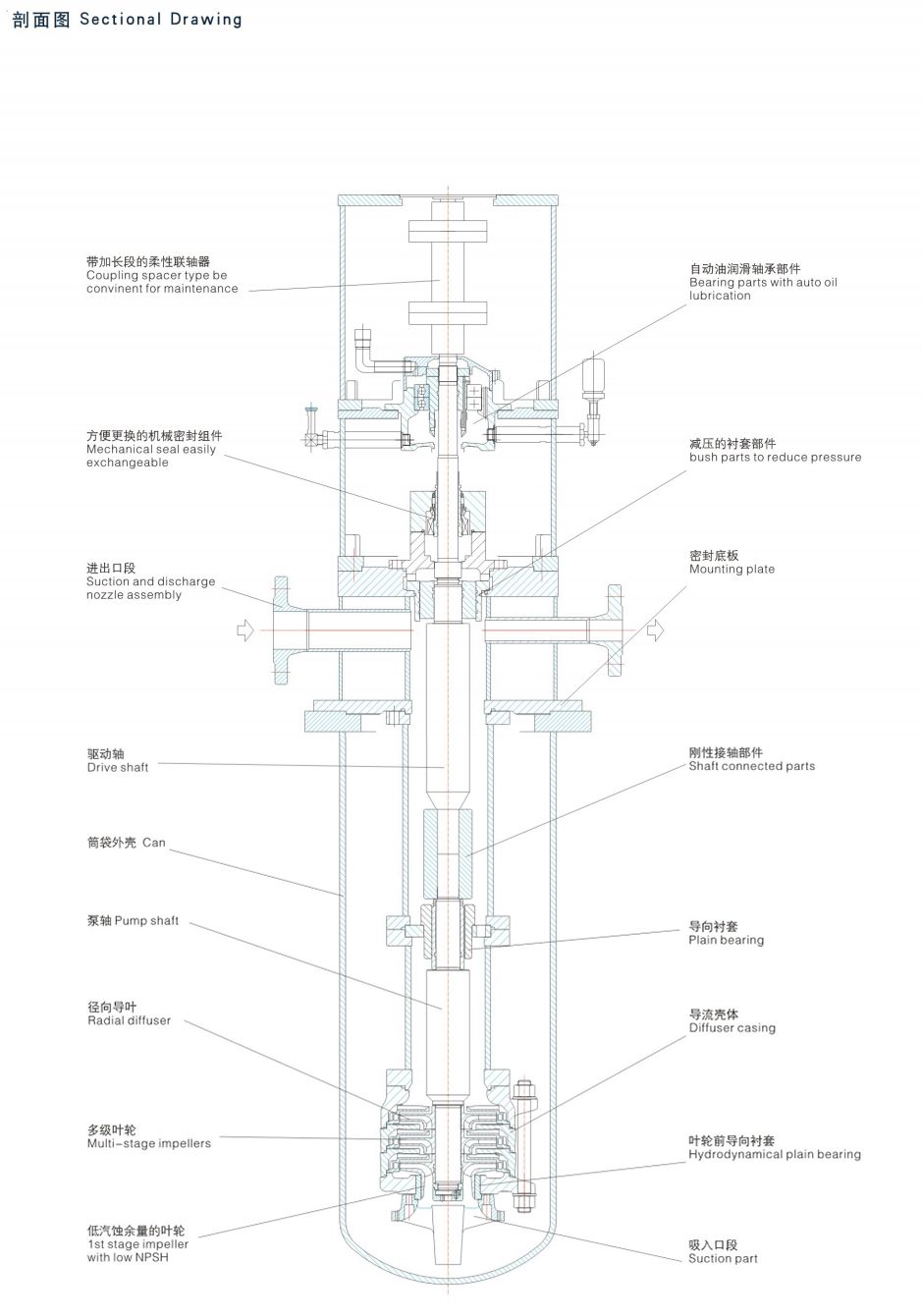

■Hydraulic Design

Different hydraulics for every pump size for high efficiency and low energy input;

1st stage with suction impeller to apply to the low NPSH values condition;

Dynamic balance grade of the rotor is G2.5 to operate stably

■Shaft and Bearing

Strong shaft design, critical speed is greater than operation speed by shaft material and bearing design;

Oil-lubricated antifriction bearing with rotation-independent automatic lubrication by internal oil circulation;

Hydrodynamic radial plain bearing at suction side ofthe pump;

Bearing spacing accordant with APl 610.

Axial force can be balanced by balance drum.

■Shaft Seal

Mechanical seal, single face, double face, tandem face;

Flush plan accordance with APl682

Throttle bushing assembly to decrease pressure inthe seal chamber

■Can Design

Can will be welded according to ASME codeVIII+IX

Copyright © 2024 ZIBO BOSHAN TIAN TI CACUUM CO.,LTD 备案号:鲁ICP备2020049334号

鲁公网安备 37030402001448号

鲁公网安备 37030402001448号