E-Mail:ttpump@163.com

Phone:+86-13615332800

Tel:+86-0533-4160533

Address:3 Yanhe East Road, Boshan, Zibo, Shandong

The SP series swirl pump is a single-stage, single suction, horizontal cantilever centrifugal pump that complies with the ISO13709 standard. The pump casing is a foot support structure. The bearings are lubricated with oil bath, and the rotor can be adjusted axially. The impeller adopts threaded connection, with high bearing strength, few parts, and high reliability. Standard design mechanical seal chamber size, suitable for different professional seal factory products. The shaft rotor system optimized for bed design has strong load-bearing capacity, stable operation, low vibration, and low operating noise. The optimized combination design of hydraulic geometric parameters of overcurrent components, combined with the correction of scientific hydraulic experiments, greatly improves hydraulic efficiency, which is more than 5% higher than traditional designs and existing domestic products on average, reaching the international advanced level.

■Almost no damage to solid objects in the medium

■Reduce the wear and tear of overcurrent components, resulting in low maintenance costs

■Good solid material passing ability, no blockage, no entanglement

■After smoothing treatment, there is no pollution to the medium

■Low NPSHr value, good anti cavitation performance

■Advanced hydraulic design, high efficiency

■Wide working range, flat curve performance

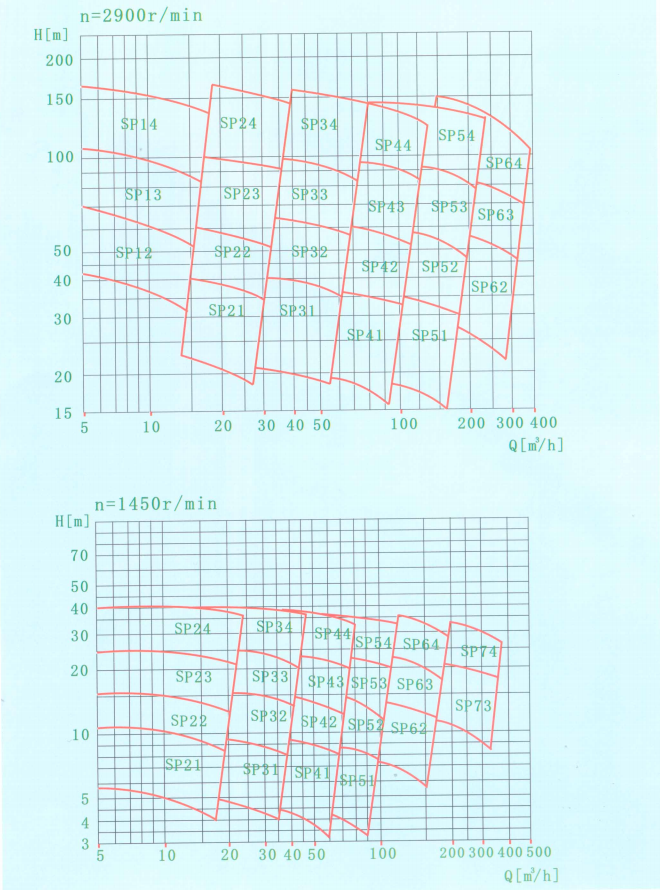

Capacities Q ~300m³/h

Heads H ~160m

Temperature -20℃-180℃

The open vortex type impeller rotates inside the pump cavity, generating a strong induced vortex field. The vortex field is forcibly expanded within the optimized hydraulic components, transferring hydraulic energy to the solid material and pushing it towards the discharge outlet. At the same time, the vortex field extends to the pump inlet, generating strong suction on the solid mixture and entering the vortex field, thus completing one cycle. Hydraulic components with unique structures can transport media with high solid and gas content.

Because the medium conveyed by the feeder does not pass through the open impeller, but through the pump chamber next to the impeller, the blockage phenomenon is completely eliminated. The solid particles carried by the medium have almost no contact with the impeller, so there is little wear on the impeller.

This series of pumps is suitable for conveying media containing various fragile fibrous, coarse and uneven, sheet-like, clustered and uneven fluid chemical products, food and semi-finished products, some lightweight slurries, urban waste or industrial waste. It can effectively handle the following tricky media:

a. Fiber materials: textiles, fur, sawdust, pulp, etc

b. Adhesive media: waste paper, paste, juice, starch, etc

c. Abrasive materials: sand, coal, coke, stones, etc

d. Vulnerable items: vegetables, fish, crystals, etc

e. Biphase fluids: extraction slurry, phosphoric acid filtrate, etc

The SP series swirl pump is a single-stage, single suction, horizontal centrifugal pump designed and manufactured in accordance with the ISO13709 standard. The main components have the following design features

Designed according to the theory of forced vortices, the optimized linear structure can achieve excellent matching with the fluid field of Xiexi, with high efficiency, large turning radius, and strong passing ability. Different cavity combinations can be designed according to the type of conveying medium, with strong adaptability. The pump casing adopts a foot support structure, with good structural and strength design, which can withstand pipeline loads to the maximum extent and work normally with good adaptability.

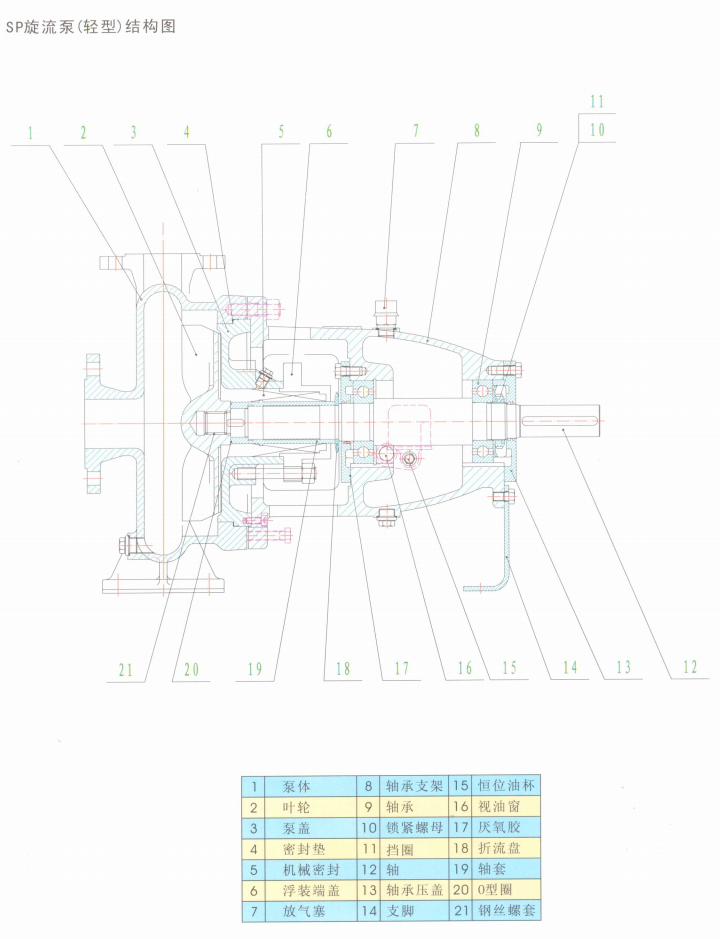

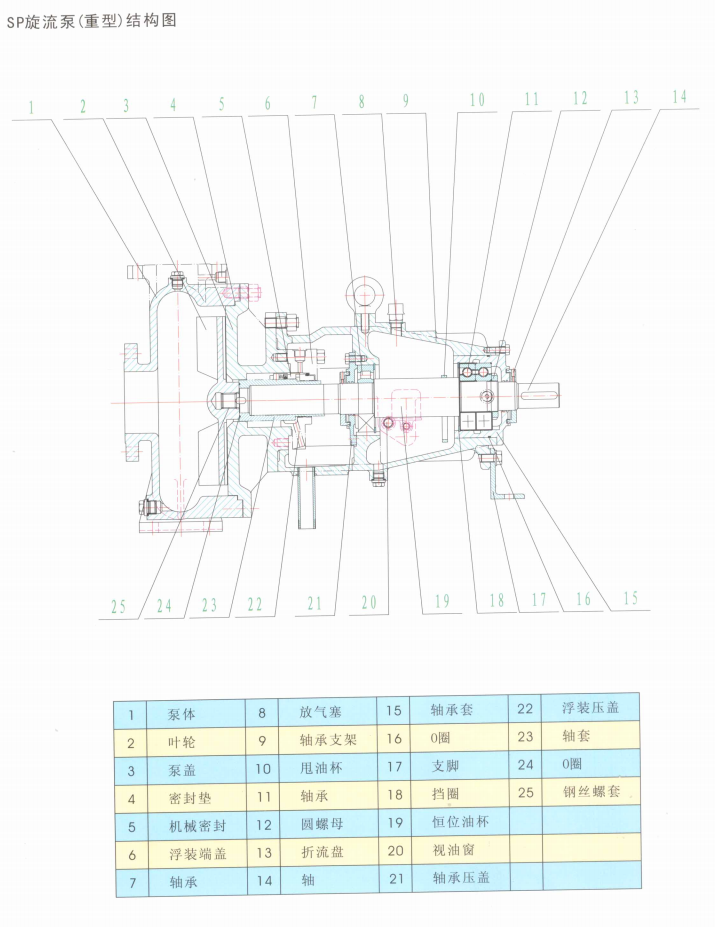

Adopting a turbine type impeller, open structure, small package angle and large outlet angle design technology, 4-12 blades, matched with the pump chamber to generate the optimal vortex field, with low hydraulic loss and high efficiency. The precisely designed back blade maximizes the balance of axial force over a wide working range, thereby reducing the problem of excessive bearing force on the shaft under variable operating conditions and improving the bearing life.

The impeller is designed with heavy-duty threaded connections and is equipped with elastic anti loosening devices, which will not loosen in case of occasional reversal.

The sealing chamber has a wide size and strong adaptability. Standard shaft seal size, can be equipped with single end and double end mechanical seals, suitable for different occasions. Special designed soft packing seals can also be used to isolate gas and slag outside the packing box through the sealing liquid in the water seal ring, extending the service life of the seal and avoiding the phenomenon of intake surge under low inlet pressure.

According to the working conditions, choose between heavy-duty or light-duty bearing forms. The heavy-duty bearing is a double row angular contact ball bearing that can withstand bidirectional axial forces. The optimized cantilever ratio, combined with precise rotor dynamic balancing (G1.0 level), reduces the radial force of the bearing. Both light and heavy bearings have a service life of over 25000 hours. The axial clearance of the rotor can be adjusted, so that after the impeller works for a period of time, the adverse effects caused by the increase in back clearance can be eliminated without replacing parts and continue to work for a certain period of time, making it convenient to make maintenance plans. Adequate fuel tank size space, sufficient storage of oil, safe purification and heat dissipation. The adjustable liquid level gauge with a minimum of 250m1 is fully replenished, and the oil level is clear, transparent, and visible. The patented design of the oil level gauge is made of high transparency and high-strength polymer materials, which are resistant to impact and not easily damaged, making it beautiful and elegant.

The bearing housing design has standard oil level and oil temperature interfaces. The bearing is designed with standard interfaces for measuring temperature and vibration, which can be displayed locally or transmitted remotely. The bearing end cover adopts an optimized labyrinth non-contact seal design, which eliminates the worry of wear and tear.

Adopting an extended metal diaphragm coupling, the shaft system has good neutrality, low vibration, and long service life. Remove the extended section without moving the motor. Simply pull out the bearing box to remove the rotor for maintenance work such as replacing vulnerable parts.

The pump and electric motor share a common base, which is "pry type" for easy transportation and installation. The shared base is installed vertically. The child can start the snail, making it convenient for basic leveling and correction.

From the direction of the driving end, the pump rotates clockwise.

According to the characteristics of different process media, the materials of the main components of the pump can be divided into the following categories: carbon steel, ductile iron CF-8(304)、CF-8M(316)、CF-3M(316L)、CN7M(Carpenter20)、N-12M(Hastelloy B)、CW-12M(Hastelloy C) Wait.

Copyright © 2024 ZIBO BOSHAN TIAN TI CACUUM CO.,LTD 备案号:鲁ICP备2020049334号

鲁公网安备 37030402001448号

鲁公网安备 37030402001448号